Flat sheet membrane filtration is a sophisticated technology used in various industrial and environmental applications to separate substances at the molecular level. This filtration method utilizes a barrier or membrane that selectively allows certain particles or molecules to pass through while blocking others based on size, shape, or chemical properties.

How Flat Sheet Membrane Filtration Works?

Principle of Operation:

Flat sheet membranes act as semipermeable barriers designed to remove particles, microbes, and dissolved molecules from liquids.

The process can be pressure-driven or concentration-driven, depending on the application.

Configuration:

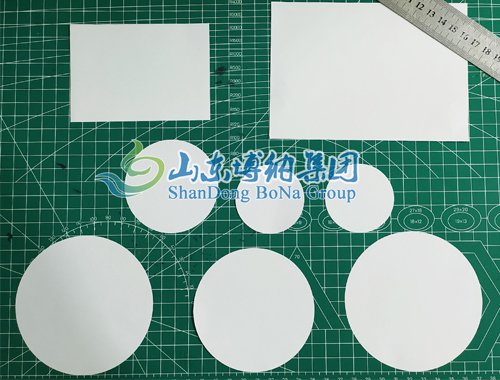

The membrane typically comes in a flat, sheet-like configuration which can be assembled in stacks or rolled in a spiral configuration for more surface area in compact applications.

These stacks or rolls are then housed in a pressure vessel where the filtration process takes place.

Types of Membranes Used

Microfiltration (MF): Removes larger particles such as sediment and bacteria.

Ultrafiltration (UF): Targets smaller particles and some large molecular weight solutes like proteins.

Nanofiltration (NF): Allows removal of smaller molecules, including divalent and larger monovalent ions.

Reverse Osmosis (RO): Highly effective in removing almost all particulate and high molecular weight solutes e.g., salts and sugars.