Ceramic membrane filtration is an advanced filtration process that employs membranes made from ceramic materials to separate fine particulate matter and microbes from fluids. This technology is distinguished by its robustness and efficiency, making it suitable for a wide range of applications across various industries.

Composition and Structure

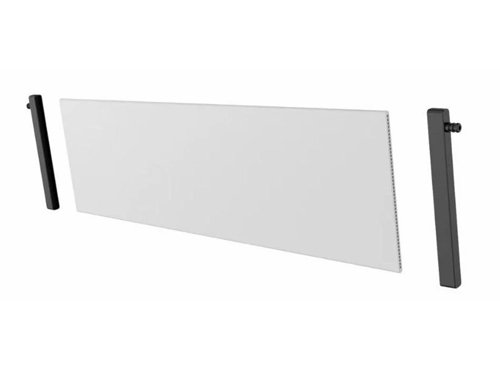

Ceramic membranes are made from inorganic materials such as alumina, zirconia, titanium dioxide, and silicon carbide. These materials grant the membranes high mechanical strength and chemical stability, allowing them to operate in extreme pH, temperature, and aggressive chemical environments. The structure of these membranes can be tubular, flat sheet, or multi-channel configurations, providing flexibility in design and application.

Explore our extensive array of commercial roll up doors by common application uses below.

Key Features

High Temperature Resilience: Ceramic membranes can withstand high temperatures, making them suitable for processes that involve hot fluids.

Chemical Resistance: They are resistant to most acids, bases, and solvents, allowing their use in a wide range of chemical processes.

Long Service Life: Due to their robust nature, ceramic membranes typically have a longer lifespan compared to polymeric membranes, although they may have a higher initial cost.

Sterilizability: Ceramic membranes can be easily sterilized using steam or hot water, making them ideal for applications in the pharmaceutical and food and beverage industries.