Microfiltration membrane generally refers to a filtration membrane with a pore size between 0.1-1 micron. Microfiltration membranes can trap particles between 0.1-1 micron. The microfiltration membrane allows macromolecules and dissolved solids (inorganic salts) to pass through, but it will intercept suspended solids, bacteria, and large molecular weight colloids. The operating pressure of microfiltration membrane is generally: 0.3-7bar. Microfiltration membrane filtration is the earliest membrane technology developed and applied in the world, using natural or synthetic polymer compounds as membrane materials. For microfiltration membranes, the separation mechanism is mainly screening and interception.

Features:

1. Separation efficiency is an important performance characteristic of micropores, which is controlled by the pore size and pore size distribution of the membrane. Because the microporous filter membrane can achieve a relatively uniform pore size, the microfiltration membrane has higher filtration accuracy and higher reliability;

2. The surface porosity is high, generally reaching 70%, which is at least 40 times faster than filter paper with the same retention capacity;

3. The thickness of the microfiltration membrane is small, and the loss caused by the adsorption of liquid by the filter medium is very small;

4. The polymer microfiltration membrane is a uniform continuum. There is no medium falling off during filtration, which will not cause secondary pollution, thus obtaining high-purity filtrate;

Optional specifications and models: 0.05um, 0.1um, 0.2um, 0.3um, 0.45um

Typical application areas:

1. Filtration and sterilization in the pharmaceutical industry.

2. Applications in the food industry (clarification of gelatin, clarification of glucose, clarification of fruit juice, clarification of liquor, recovery of beer residue, sterilization of white beer, skimming of milk, production of drinking water, etc.).

3. Applications in the health care product industry: production of animal peptides and plant peptides; clarification and concentration of health tea and coffee powder; vitamin separation, health wine impurity removal, etc.

4. Application in biotechnology industry.

5. Pretreatment of reverse osmosis and nanofiltration processes.

6. Removal of algae and particulate impurities in surface water such as reservoirs, lakes, rivers, etc.

Ultrafiltration membrane is a microporous filtration membrane with consistent pore size specifications and a rated pore size range of less than 0.01 micron. By applying appropriate pressure on one side of the membrane, solute molecules smaller than the pore size can be screened out to separate particles with a molecular weight greater than 500 Daltons (atomic mass units) and a particle size greater than 10 nanometers. Ultrafiltration membrane is one of the earliest polymer separation membranes developed. Ultrafiltration devices were industrialized in the 1960s. It can separate target products of different molecular weights, thereby replacing traditional purification processes such as activated carbon decolorization, resin impurity removal, and crystallization extraction to achieve the purposes of decolorization, impurity removal, and product classification.

Features:

1. High thermal stability and chemical stability

2. Imported raw materials ensure high quality

3. No dead ends design, not easy to pollute

4. Membrane components are easy to replace

5. Membrane elements of various specifications are available for selection

6. The membrane core has high filling density and low cost per unit membrane area.

Optional specifications and models: 1000D, 2000D, 3000D, 5000D, 8000D, 10KD, 20KD, 30KD, 50KD, 70KD, 100KD, 300KD, 500KD, 800KD

Typical application areas:

1. Clarification and concentration of fermentation broth in pharmaceutical and biochemical industries;

2. Whey protein separation and gelatin concentration;

3. Juice concentration and separation;

4. Separation and refining of traditional Chinese medicine extracts;

5. Refining of low-alcohol liquor, clarification and filtration of wine;

6. Preparation of medical sterile water and water for injection;

7. Industrial water pretreatment and pure water purification and sterilization;

8. Oil and water separation.

Nanofiltration membrane: The molecular weight cutoff of nanofiltration membranes is between reverse osmosis membranes and ultrafiltration membranes, about 200-800 daltons. Retention characteristics: It preferentially intercepts divalent and multivalent anions. The interception rate of monovalent ions is related to the concentration and composition of the feed liquid. Nanofiltration is generally used to remove organic matter and pigments in surface water, hardness and partial removal of dissolved salts in groundwater, and is used for the extraction and concentration of substances in food and biopharmaceutical production. The operating pressure of nanofiltration membranes is generally 3.5-30bar.

Features:

1. Accurate molecular weight cutoff

2. Membrane components are easy to replace

3. No dead ends design, not easy to pollute

4. Imported high-quality membrane materials, large flux and high stability

5. Membrane elements of various specifications are available for selection

6. The membrane core has high filling density and low cost per unit membrane area.

Optional specifications and models: 100D, 150D, 200D, 300D, 500D, 600D, 800D

Typical application areas:

1. Softened water treatment

2. Chemical wastewater treatment

3. Recycling of precious metals

4. Removal of harmful substances in drinking water

5. Dye decolorization or concentration, heavy metal removal, acid purification

6. Concentration and refining of various proteins, amino acids, and vitamins in the fields of food, beverages, pharmaceuticals, etc.

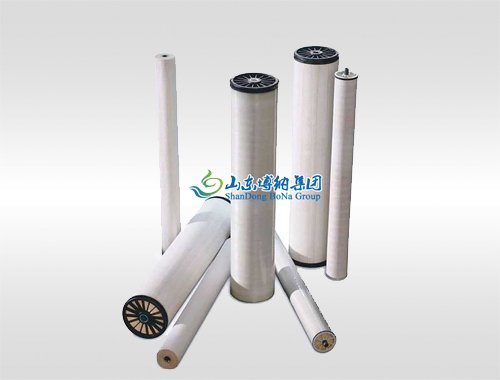

Reverse osmosis membrane is the core component to realize reverse osmosis. It is an artificial semipermeable membrane with certain characteristics made by simulating biological semipermeable membrane. It is a very fine membrane separation product that can intercept substances larger than 0.0001 microns. It can effectively intercept all dissolved salts and organic matter with a molecular weight greater than 100, while allowing water molecules to pass through. There are two types of reverse osmosis membrane structures: asymmetric membrane and homogeneous membrane. The currently used membrane materials are mainly cellulose acetate and aromatic polyamide. Its components include hollow fiber type, roll type, plate and frame type and tube type. It can be used for chemical unit operations such as separation, concentration, and purification, and is mainly used in pure water preparation and water treatment industries.

Product advantages:

1. It should have high desalination rate under high flow rate;

2. Has high mechanical strength and service life;

3. Can function under low operating pressure;

4. Can withstand the influence of chemical or biochemical effects;

5. Less affected by factors such as pH value and temperature;

6. The raw materials for film making are easy to source, easy to process and low in cost.

Optional specifications and models: RO1, RO2, RO3, RO4, RO5, RO6, RO7, SW30, BW30

Application scope:

Reverse osmosis membranes are widely used in the fields of electric power, petrochemical industry, steel, electronics, medicine, food and beverage, municipal administration and environmental protection. They are used in seawater and brackish water desalination, boiler water supply, industrial pure water and electronic grade ultrapure water preparation, and drinking purity. It plays an important role in water production, wastewater treatment and specialty separation processes.